Afes Software Foundation Design Free Download

Weights Working weight, with dipper and standard links 3066000.0 lb 1390714.0 kg Ballast (furnished by customer) 667150.0 lb 302614.0 kg Note These weights will vary slightly depending upon dipper and optional equipment selection These weights will vary slightly depending upon dipper and optional equipment selection Note All specifications are based on a 56 m3 (73 yd3) dipper and standard 200.7 cm (79 in) treads All specifications are based on a 56 m3 (73 yd3) dipper and standard 200.7 cm (79 in) treads. Front End Type One piece, forged, seamless tubular dipper handle and wide-spread boom point sheaves equipped with hoist ropes and dipper padlocks to stabilize dipper handle. One piece, forged, seamless tubular dipper handle and wide-spread boom point sheaves equipped with hoist ropes and dipper padlocks to stabilize dipper handle. Rope Data: Hoist – No. 2 2 Rope Data: Boom suspension – No.

4 4 Rope Data: Dipper trip – No. 1 1 Rope Data: Hoist – Diameter 2.75 in 70.0 mm Rope Data: Boom suspension – Diameter 3.25 in 83.0 mm Rope Data: Dipper trip – Diameter 0.75 in 19.0 mm Rope Data: Note High impact ropes available as an option High impact ropes available as an option Crowd HydraCrowd, hydraulic power skid, located at the front center of the revolving frame deck, powers a large hydraulic cylinder to move the dipper handle fore and aft. HydraCrowd, hydraulic power skid, located at the front center of the revolving frame deck, powers a large hydraulic cylinder to move the dipper handle fore and aft.

Crowd (Optional) Rope Crowd, the crowd machinery is located at the front center of the revolving frame, consisting of motor, brake, drum and gearing. Plastic-impregnated crowd and retract ropes are used to move the dipper handle fore and aft. (Optional) Rope Crowd, the crowd machinery is located at the front center of the revolving frame, consisting of motor, brake, drum and gearing. Plastic-impregnated crowd and retract ropes are used to move the dipper handle fore and aft. Dimensions (Approximate) – Optimal Working Ranges* Dumping height – with clearance to open dipper door 28.9 ft 8.8 m Cutting height (maximum) 53.5 ft 16.3 m Cutting radius (maximum) 80.0 ft 24.4 m Radius of level floor 56.1 ft 17.1 m Revolving frame tail swing radius 30.5 ft 9.3 m Note Optimal working ranges based on loading a Cat 795F AC truck. Optimal working ranges based on loading a Cat 795F AC truck.

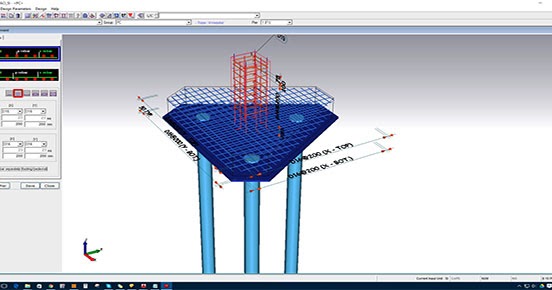

Sep 27, 2015 - 2 min - Uploaded by Tube 4YouAFES-Foundation Design Software-Footing Design (1/2) Civil Engineering - Duration: 2:50.

Note *All specifications are based on a 56 m3 (73 yd3) dipper and standard 200.7 cm (79 in) treads. *All specifications are based on a 56 m3 (73 yd3) dipper and standard 200.7 cm (79 in) treads. Tried and True AC IGBT Electric Drive System You will experience greater machine uptime, lower operating costs, and faster cycle times via our AC electric rope shovel designs that leverage institutional knowledge built on 30 years of experience commissioning more than 200 AC equipped machines worldwide. A Simpler System A streamlined AC system design that runs smoother, has fewer parts, and is easier to maintain, are the benefits you will realize, and the result of three decades of continuous improvement. Comfort Infused, State-of-the-art Operator’s Cab and Station Providing more comfort, added safety, and greater reliability, our newly designed state-of-the-art operator’s cab will help you produce more. The product of a multi-year collaboration with mining companies and rope shovel operators from across the globe, our Design Engineers, armed with insights into the aspects most desired by you, have designed what we believe to be the most comfortable and productivity-enhancing operator’s cab in the industry. Improved Performance Increase productivity, and your bottom line, with our comfort-infused cab.

Safety, Reliability and Productivity Advantages Afforded by Our Unique Design Greatly improved digging efficiency, safety, and component life are the results of our unique, yet robust front-end design, particularly when compared to rack-and-pinion systems. Faster Cycle-times, Improved Line-of-sight, and Safer Maintenance Enhance both loading safety and productivity at your mine with a lighter front-end that affords better line-of-sight and serviceability. • Faster swing times resulting from reduced swing inertia of lighter front-end • Improved left-hand line-of-sight with deck-mounted crowd machinery that reduces visibility-impeding components on the boom • Reducing fall hazards, deck-mounted crowd machinery allows the majority of crowd maintenance to be completed from the protection of the machinery house deck Reduced Cracking and Extended Component Life Experience greater uptime and component reliability with our unique, yet robust front-end design. • Highly crack resistant one-piece, forged dipper handle • Extending boom and dipper handle life, rotating handle design transmits torsional stress into the hoist ropes • Reducing wear and cracking at the boom/dipper handle junction, crowd and retract ropes or hydraulic fluid absorb kickback force caused by dipper colliding with poorly shot material • Replacing racks and pinions with tubular handle and ropes or hydraulic cylinder greatly reduces lube usage Easier, More Efficient Digging Realize more productive and efficient digging facilitated by our wide-set boom point sheaves. • Twin hoist ropes balance dipper pull in the bank via wide-set boom point sheaves, automatically distributing digging force where it is needed most Simplified Maintenance Get your primary loading tool back to work quickly with simpler, more straight-forward maintenance. Coolsat Serial Downloader. Results Are What You’ll Get from the HydraCrowd System The HydraCrowd system provides outstanding performance and high reliability. This innovative system goes a step further than the Rope Crowd system, making maintenance more predictable and keeping your rope shovel in production longer.

Eliminates Routine Crowd/Retract Rope Replacements HydraCrowd extends maintenance intervals and improves your overall productivity with a patented innovative design that replaces crowd and retract ropes with a hydraulic cylinder. Avoid the Leading Cause of Rope Shovel Downtime for Over a Century Spend more time digging, and less time performing unplanned dipper maintenance with the LatchFree Dipper System. The first successful solution to the number-one cause of rope shovel downtime, the LatchFree Dipper System replaces the maintenance-intensive latch assembly with a strong steel link mounted to the dipper back, away from material flow. To ensure you achieve maximum benefits, the system comes complete with a comprehensive training program. Meet the Challenges of Any Mining Environment with Two Design Options Providing extended dipper life and optimal fit with your application, our FastFil™ and Straight-Side Dippers help you move more. • Manufactured from cold-weather, impact-resistant, high strength steel for strength and durability • Stress relieved dipper back to prevent cracking • Key welds inspected using nondestructive testing • Expertly sized for your application • Designed for easy repair Straight-Side Dipper – Maximized Payload Capability Offering a larger payload range, our Straight-Side Dipper maintains quality and reliability of our FastFil Dipper design. • Box shape design accommodates larger dipper sizes • Available in sizes up to 61.2 m3 (80 yd3) FastFil Dipper – Faster, Fuller Dipper Loads Improving fill factors and helping you hit your productivity targets the trapezoidal shape of our FastFil Dipper accommodates the natural configuration of the load, eliminating voids that occur with box-shaped dippers.

• Trapezoidal shape eliminates the void that occurs at the back of the dipper with the traditional dipper shapes • Improved maneuverability and faster swing times resulting from reduced dipper size and weight • Improved bank penetration and elimination of bulldozing for material turbulence due to optimized lip and rake angles • Reduced load and dump times facilitated by shorter dipper body • Fill factors average >100% (110% typical) • Available in sizes up to 49.7 m3 (65 yd3). Providing optimum speed and cycle time, all while extending component life, our swing system is designed to help keep your rope shovel swinging longer and filling trucks faster. Even Loading Achieve maximum component life with our swing system design that ensures reduced and even swing rack wear. • Eliminating the need to rotate the swing rack, two swing gearcases, positioned 180° apart, produce even swing rack wear • Reducing wear on the swing rack and swing pinions, straddle-mounted, dual-output pinions decrease tooth loading Better Serviceability Mean-time to repair is reduced, as most repairs involve the third rail, rather than the rollers. • The easy-to-replace third rail, rather than roller flanges or the swing rack, serves as the primary wearing part in the system, greatly simplifying maintenance • Provides roller access without jacking up the upper half of the machine. Helping You Enhance Safety and Productivity Through Technology Aimed at enhancing the productivity and profitability of your rope shovel, we currently offer a combination of Cat Electric Rope Shovel technology solutions including MineStar offerings. Cat MineStar Helping you achieve your goals for enhanced mine site safety, improved efficiency, reduced operating costs, and greater profitability, Cat MineStar provides the most comprehensive suite of mining technology products in the industry.

It consists of a number of configurable capability sets – Fleet, Terrain, Detect, Health, and Command – that allow you to scale the system to your mine site needs. Cat MineStar helps you manage everything from material tracking to sophisticated real-time fleet management, machine health systems, autonomous equipment, and more. The Cat 7495 is currently able to utilize three of the Cat MineStar capability sets: • Fleet – Fleet provides real-time machine tracking, assignment and productivity management, providing a comprehensive overview of all your asset operations from anywhere in the world. • Terrain – Terrain enables high-precision management of drilling, dragline, grading and loading operations through the use of guidance technology. It increases machine productivity and provides you real-time feedback for improved efficiency.

Finite Element Design Concrete Structures Rombach Pdf Viewer. • Health – Health delivers critical event-based machine condition and operating data for your entire fleet. It includes comprehensive equipment health and asset monitoring capabilities with a wide range of diagnostic, analytic and reporting tools. EMSolutions Cat EMSolutions puts your dealer’s expertise and services to work with the latest equipment management technologies to help you reduce operating costs, get more value from your equipment and meet the unique needs of your business.

With five levels of EMSolutions to choose from, you’ll get all the support you want, without paying for services you don’t need. Services can include condition monitoring (CM) services through the use of Cat Equipment Care Advisor (Cat ECA).

Optional Technology Solutions: AccuLoad Improve productivity with real-time dipper load feedback directly to operators. • Improves productivity by allowing operator to monitor load and shift performance • Reduces machine and truck overloading Optional Technology Solutions: Bearing Temperature Monitoring Better maintenance predictability and reduced risk of failure via bearing temperature monitoring, a system that monitors bearing temperature and alerts operator of high temperatures. • Helps predict maintenance through bearing temperature trending • Reduces risk of major failure Please speak to your local dealer for more information on the technology solutions for your 7495 electric rope shovel. Rugged Structures Designed and Fabricated to Withstand Your Extreme Mining Conditions To extend service life and ultimately reduce your maintenance cost, all major rope shovel structures are designed for durability and dependability.

Extended performance in the harsh mining conditions you face daily is accomplished through selection of high-strength steels, and rugged castings, joined and thermally stress-relieved to create a reliable shell capable of one of the most productive loading tools in the industry. • Manufactured from cold-weather, impact-resistant, high strength steel for strength and durability • Full penetration, profiled and ground welds at critical junctures • MT, UT, and X-ray inspections on select welds ensure quality • Structures are stress relieved to prevent cracking • Manholes and ladders assist inspection • White painted interiors facilitate crack inspection. Enhanced Maneuverability, Extended Component Life, and Consistent Reliability Are the Foundation of This Powerful Machine Intended to enhance digging/loading capability, ground footing, and mobility, a newly designed propel system and battle tested crawlers come standard on all Cat electric rope shovels. • Stress relieved crawler frames resist cracking • Lower rollers design withstands periodic single-point ground reaction caused by uneven pit floors • Crawler-mounted propel motors facilitate maintenance and reduce misalignment • Upward slanted propel motor shelves protect components from rocks and water • Elevated drive tumbler isolates planetary drive from ground impact shock loads • Sprocket-style drive tumbler lugs provide a large area of contact against the crawler links for extended tumbler and link life • Straddle-mounted rollers improve component wear and extend life. Sharing your commitment to safety, and driven by our commitment to Zero Harm, we work tirelessly to design the safest machines possible to protect your most important asset; your employees. Lowering your operating costs and maximizing your rope shovel’s uptime and productivity is of supreme importance to us.

To that end, we continually strive to automate maintenance procedures, extend maintenance intervals, and simplify maintenance activities for our electric rope shovels. Commitment Makes the Difference Cat dealers offer a wide range of solutions, services and products that help you lower costs, enhance productivity and manage your operation more efficiently. From the time you select a piece of Cat equipment until the day you trade or sell it, the support you get from your Cat dealer makes the difference. Dealer Capability Cat dealers provide the level of support you need, on a global scale.

Dealer expert technicians have the knowledge, experience, training and tooling necessary to handle your repair and maintenance needs, when and where you need them. Service Support Every piece of Cat equipment is designed and built to provide maximum productivity and operating economy throughout its working life. Your Cat dealer is a valued partner, available whenever you need them. • Cat Rebuild and Remanufactured options.

• Best-in-class product expertise. • Improve your efficiency with operator training. Aimed at advancing a novice operator to expert levels in a rapid time frame, our combination of on-site and computer-based training provides all the tools your staff will need.

To help maximize your investment in a Cat electric rope shovel, we provide on-site operator training assessments, on-site electrical and mechanical maintenance training, and a variety of computer-based training options. Meeting the needs of today without compromising the needs of tomorrow is the goal for all Cat machinery. The commitment to helping you operate safely and sustainably is affirmed in the production of the 7495 rope shovel. Cat Rope Shovel Sustainability – Electric Power More efficient than diesel powered machines, Cat electric rope shovels are entirely electric and therefore experience less heat loss. Cat Rope Shovel Sustainability – Regenerative Power Cat electric rope shovels use regenerative braking technology to convert kinetic energy from shovel motions into electrical energy when braking.

The electrical energy that is generated is then fed back to the grid. Without regenerative braking, the kinetic energy would be burned off as heat. Cat Rope Shovel Sustainability – Long Life Cycles Fewer component change-outs result in less waste. Component change-out intervals for electric rope shovels are generally longer than those for similar-sized hydraulic machines. Cat Rope Shovel Sustainability – Rebuilds Saving you money and reducing waste in the environment, electric rope shovel motors and gearcases can be rebuilt.